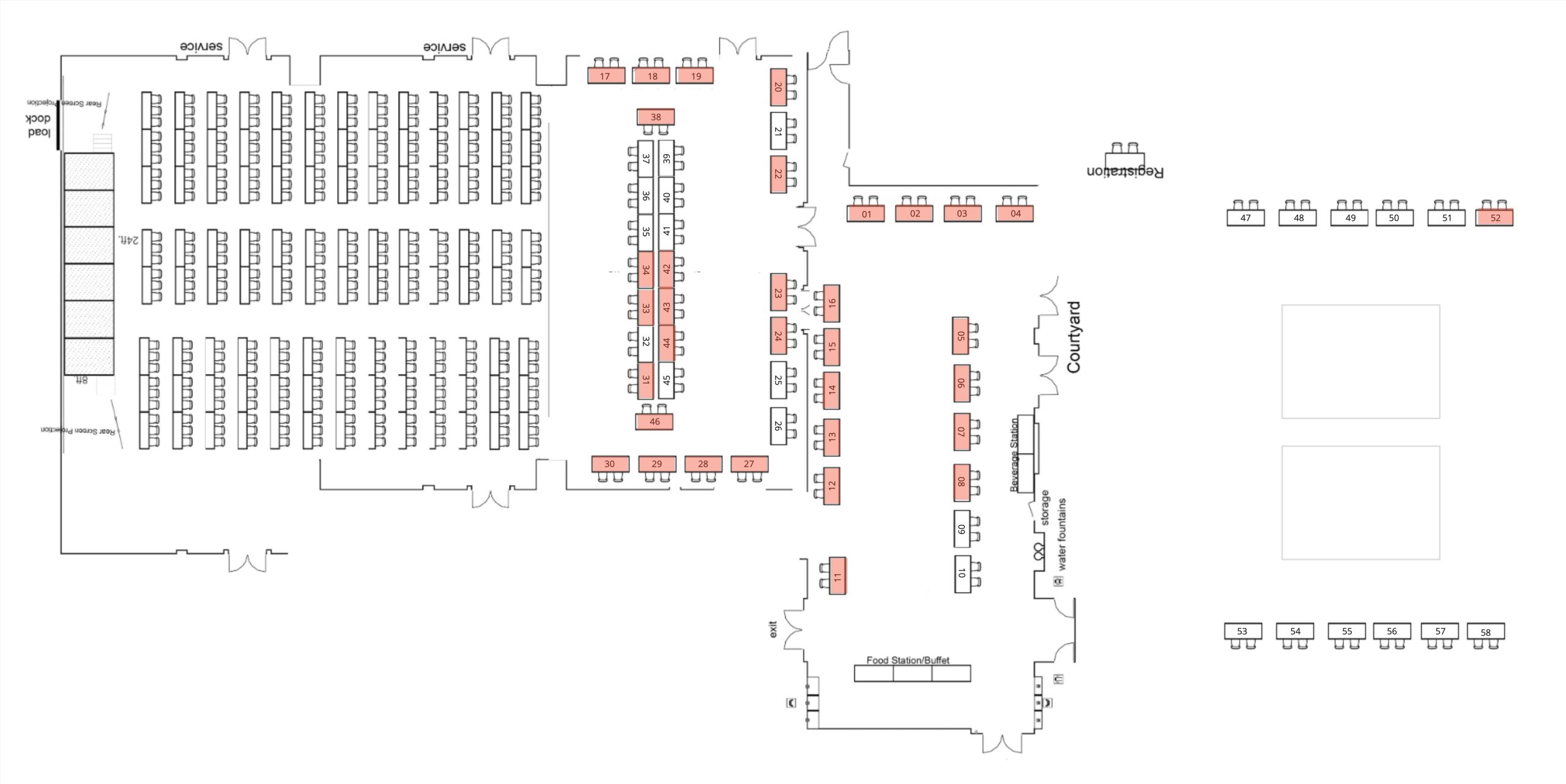

| Floor Plan

| Exhibitor Categories

Manufacturing Execution Systems (MES)

track and document the transformation of raw materials into finished goods, providing real-time production management to drive enterprise-wide compliance, quality and efficiency

Distributed Control Systems (DCS)

use decentralized elements to control dispersed systems, such as automated industrial processes or large-scale infrastructure systems

Computerized Maintenance Management Systems (CMMS)

help organizations track and manage maintenance and repair activities for their facilities, equipment and other assets in one place

Asset Performance Management (APM)

combines process, operational and machine-level data through dashboards to monitor machine and plant health

Design & Visualization

tools transform raw ideas into intuitive HMIs and immersive VR simulations for smarter, faster production

Power Control

drives continuous flow of valuable process and diagnostic data that informs the design environment, visualization systems and information software

Industrial Control Systems

improve processes and production quality at every stage of your operation and provide seamless data exchange

Smart Devices

are self and system-aware assets that acquire, process and monitor operating data

Robotics

accelerate autonomous / semi-autonomous operations and contribute to systems that are more intelligent, intuitive and flexible

Analytics

use data to solve manufacturing bottlenecks, optimize output and quality and provide new insights, tapping into the power of Industrial AI

Production Logistics

delivers an orchestrated, agile, zero touch material flow through manufacturing operations with autonomous mobile robots (AMRs)

Quality Management Systems (QMS)

standardize and automate quality documentation, processes and measurements

Supply Chain Planning (SCP)

combines data from multiple departments to sync demand and supply forecasting to improve inventory accuracy and production management

Enterprise Resource Planning (ERP)

automates front- and back-office processes across business management and related functions

Production Monitoring

provides seamless connectivity to machines on the plant floor, delivering transparent, real-time operational KPIs like Overall Equipment Effectiveness (OEE)